Fusion/ CNC Wax block / Casting / Modeling

Materials and software

-

Fusion 360 in design, mesh, and manufacturing sections

-

CNC mill - Create Wax Block

-

OMOO - to create the mold

-

stone - to create the mold

Fusion Work

-

Found an stl model online

-

STL models are difficult to work with because you dont get much control over the model

-

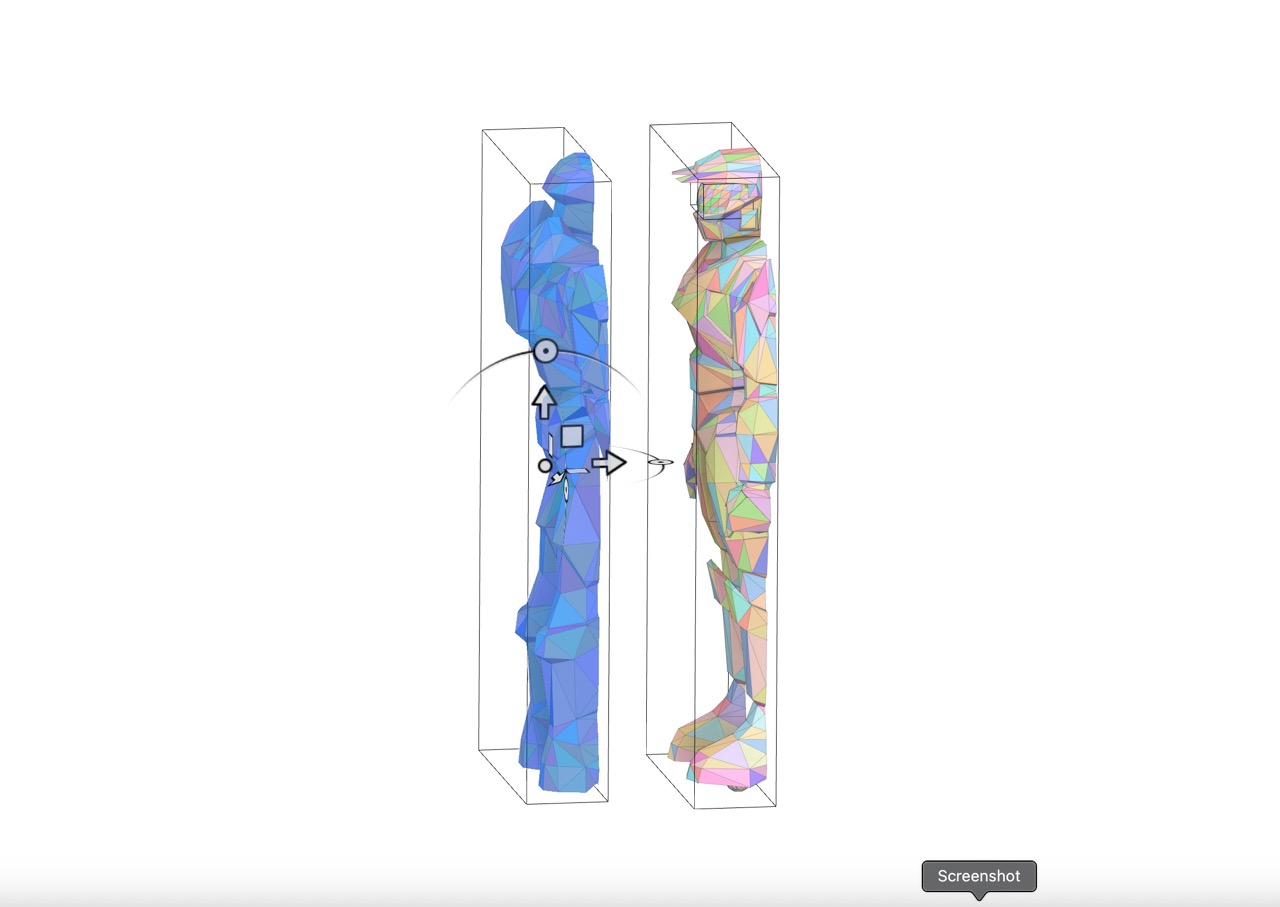

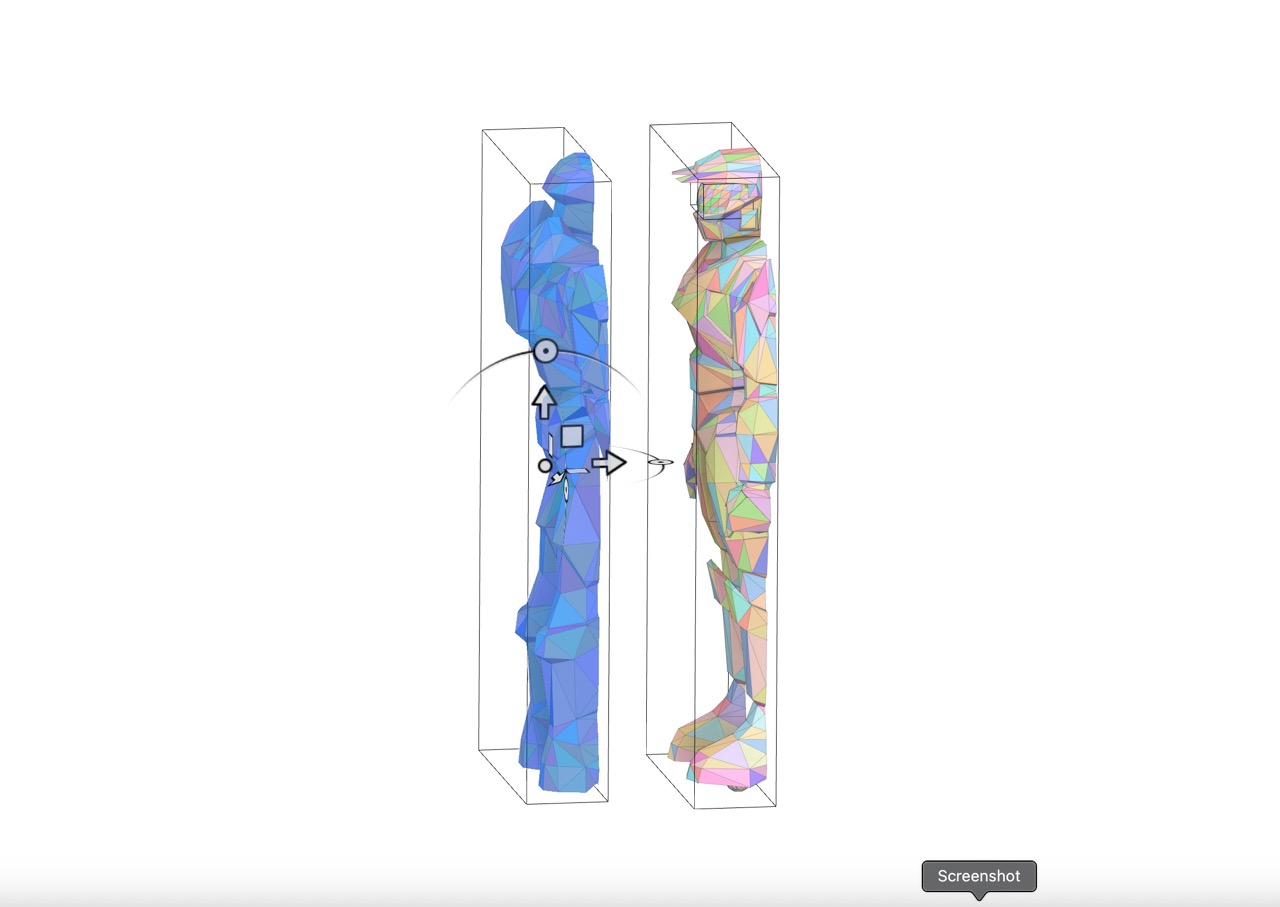

Had to convert to mesh to work with it

-

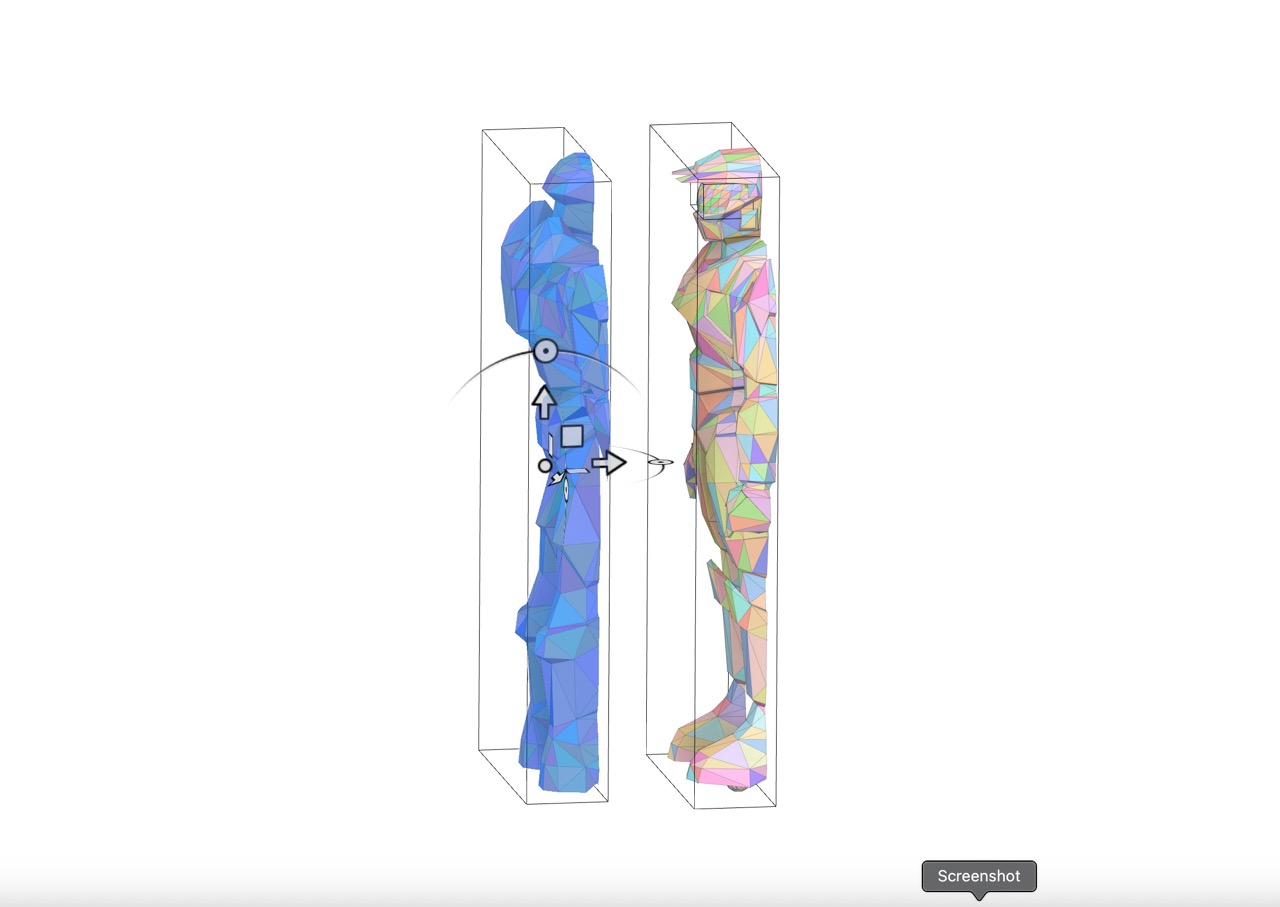

I had to use the mesh workspace to create a mold for the model

-

Then I had to stitch together all the triangle parts it built to create a solid model

-

Then I had to create a box around the model to create a mold

-

Then I also had to split the model in half to create a two part mold

-

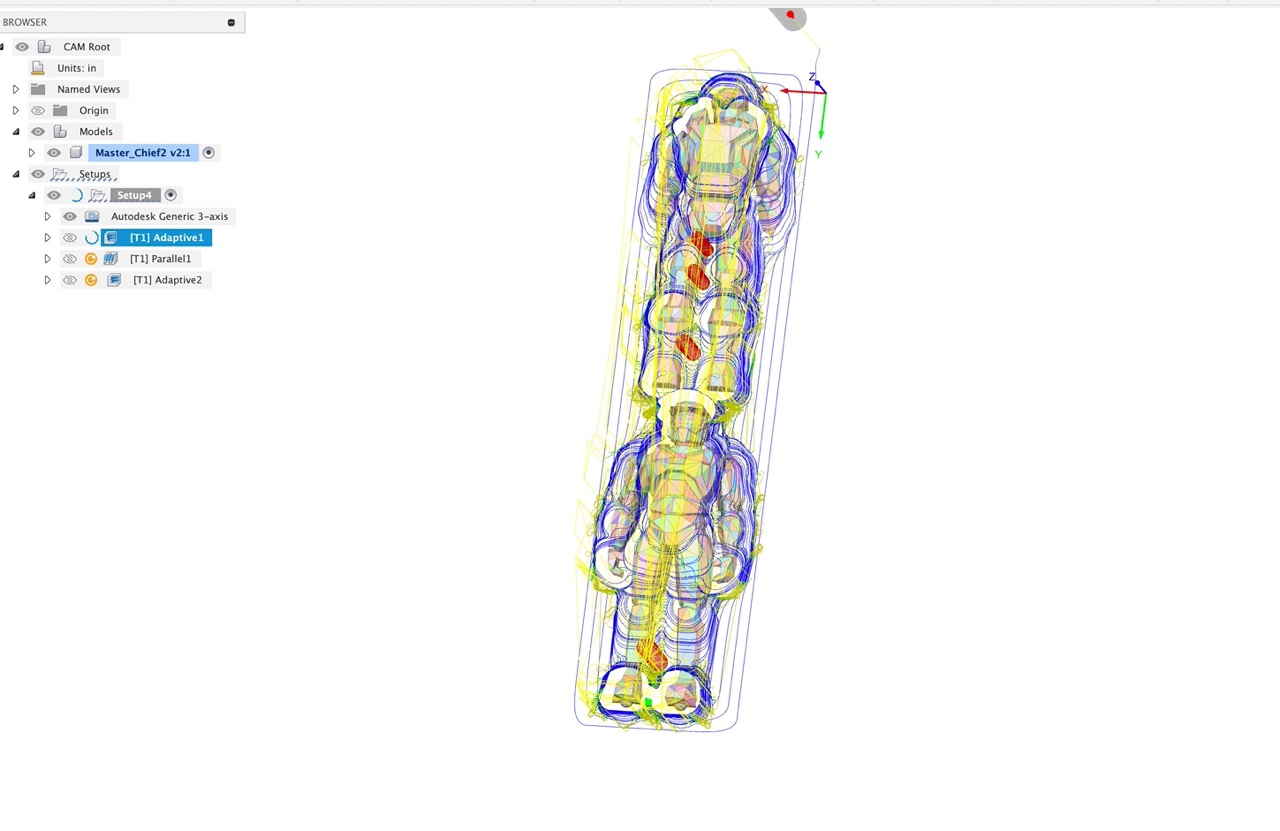

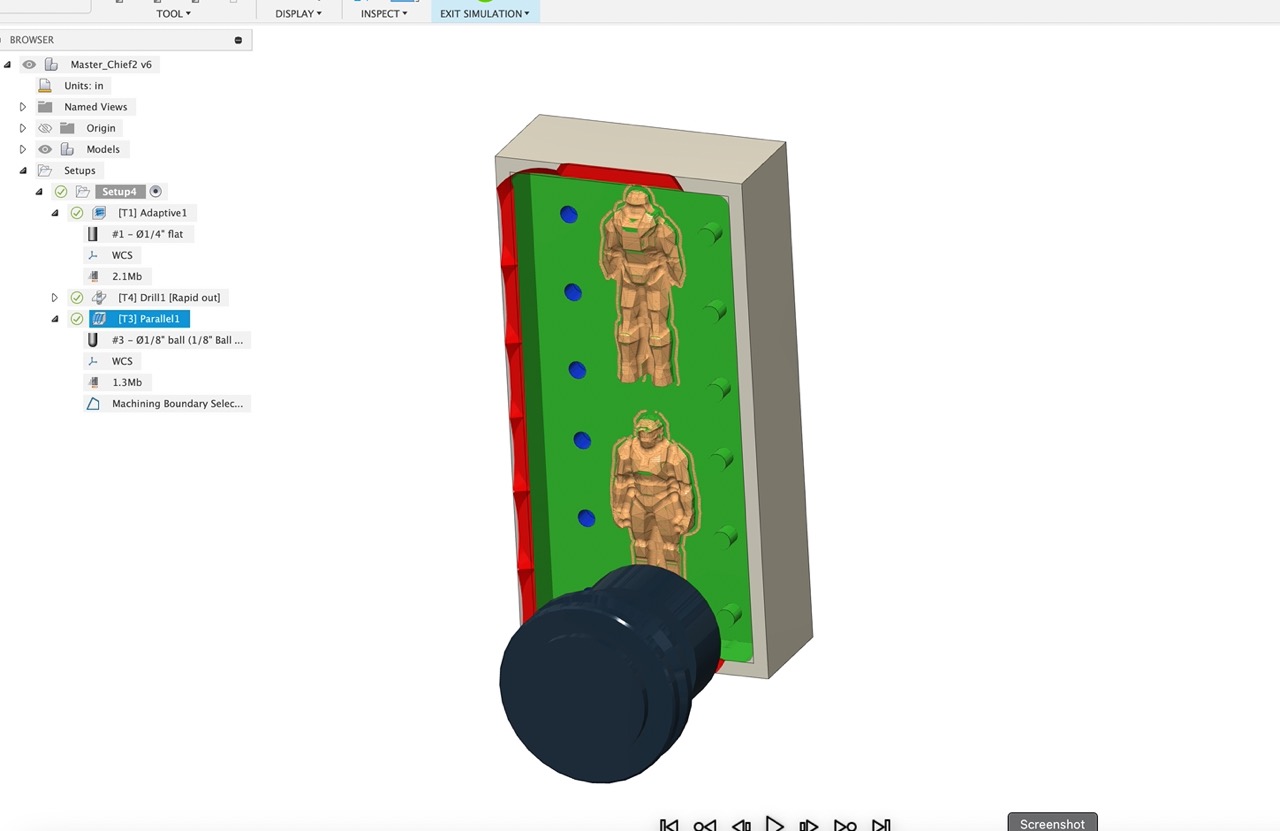

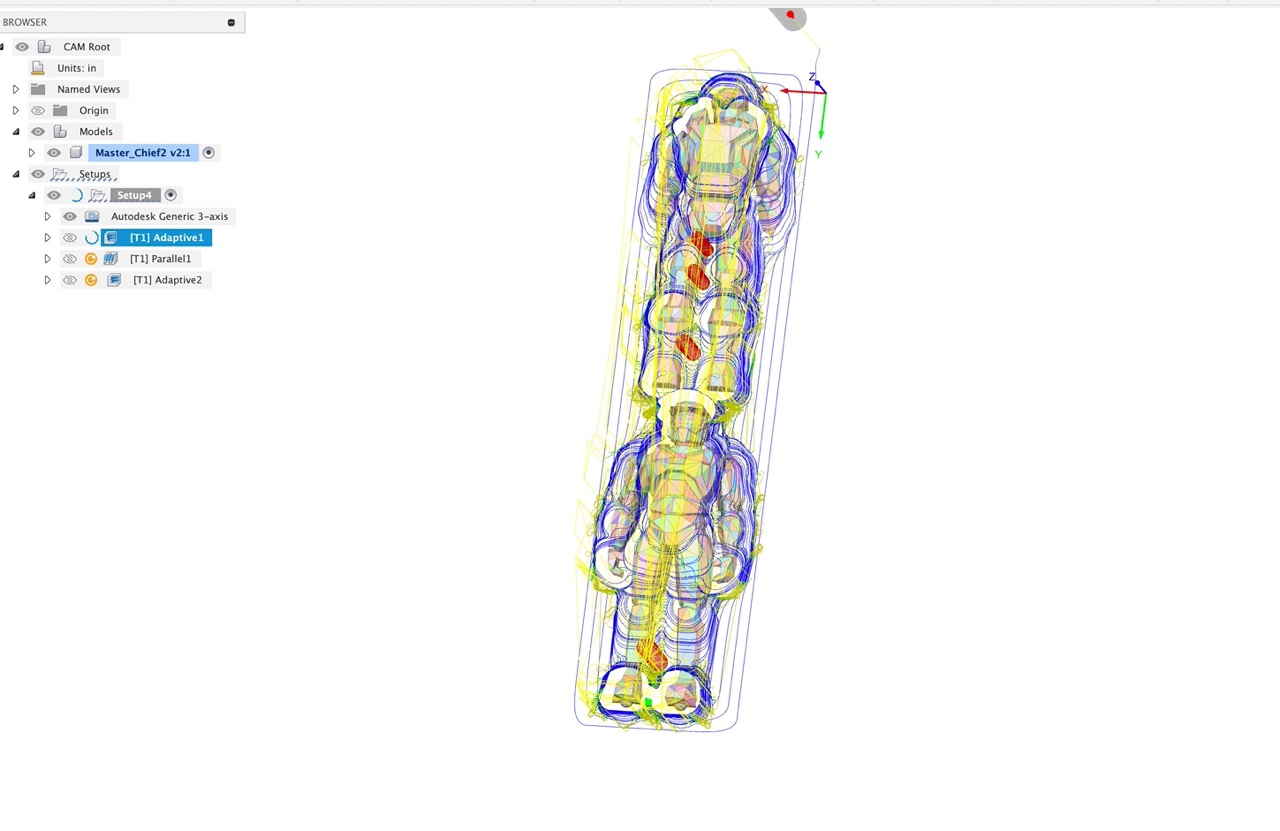

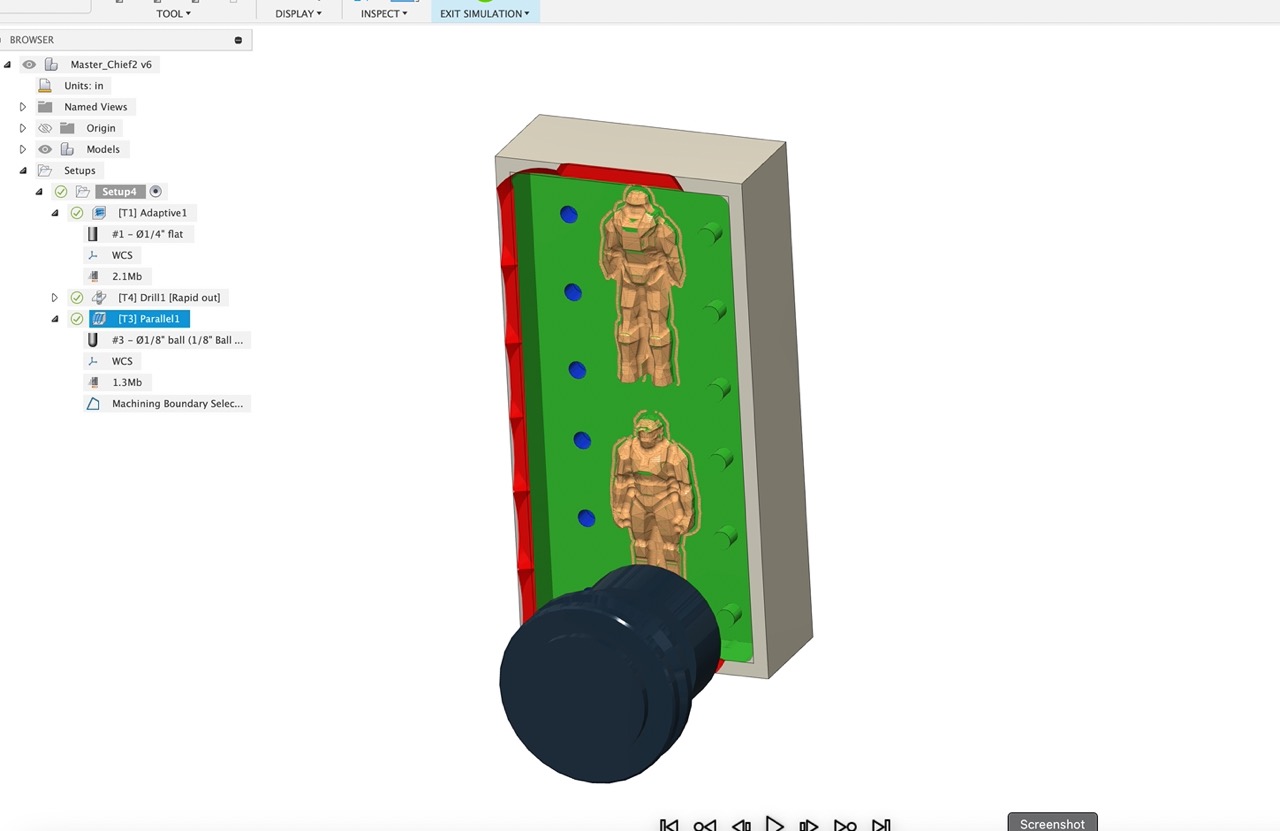

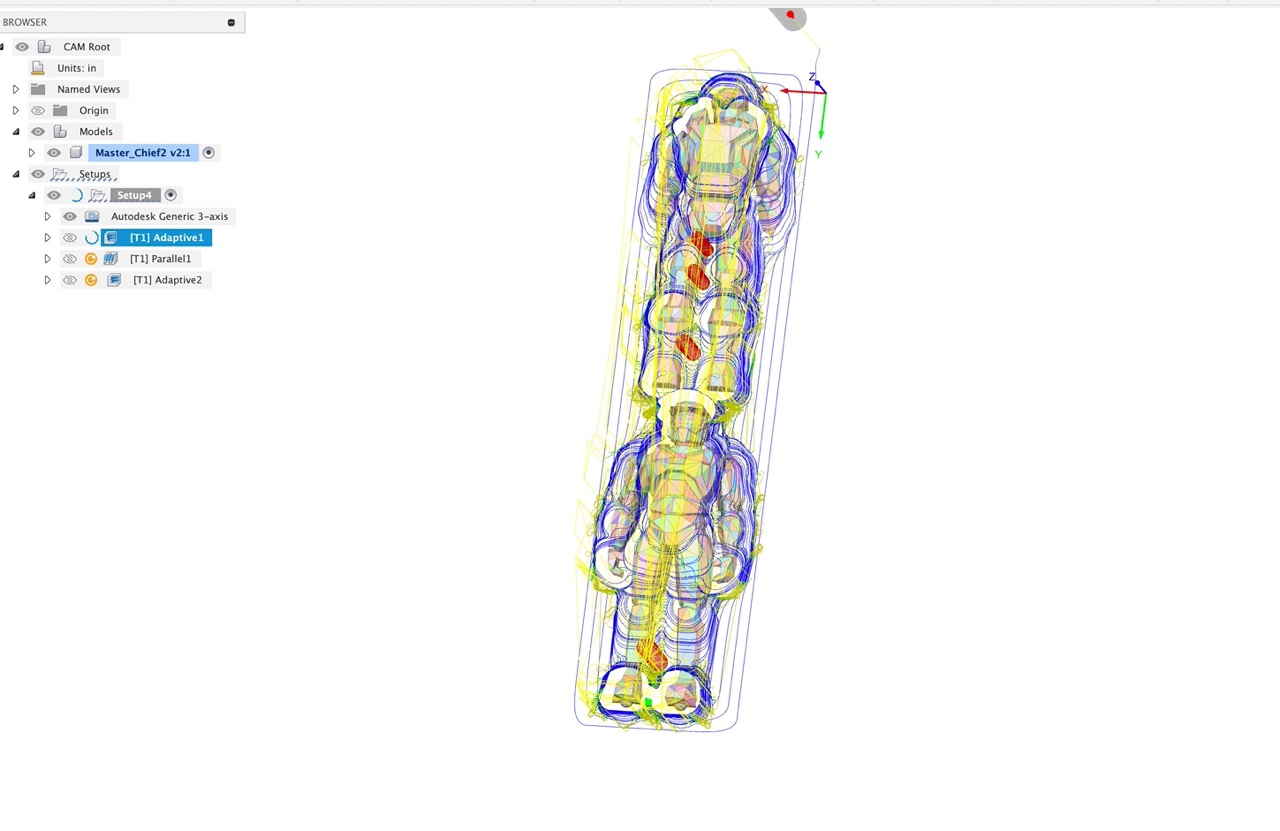

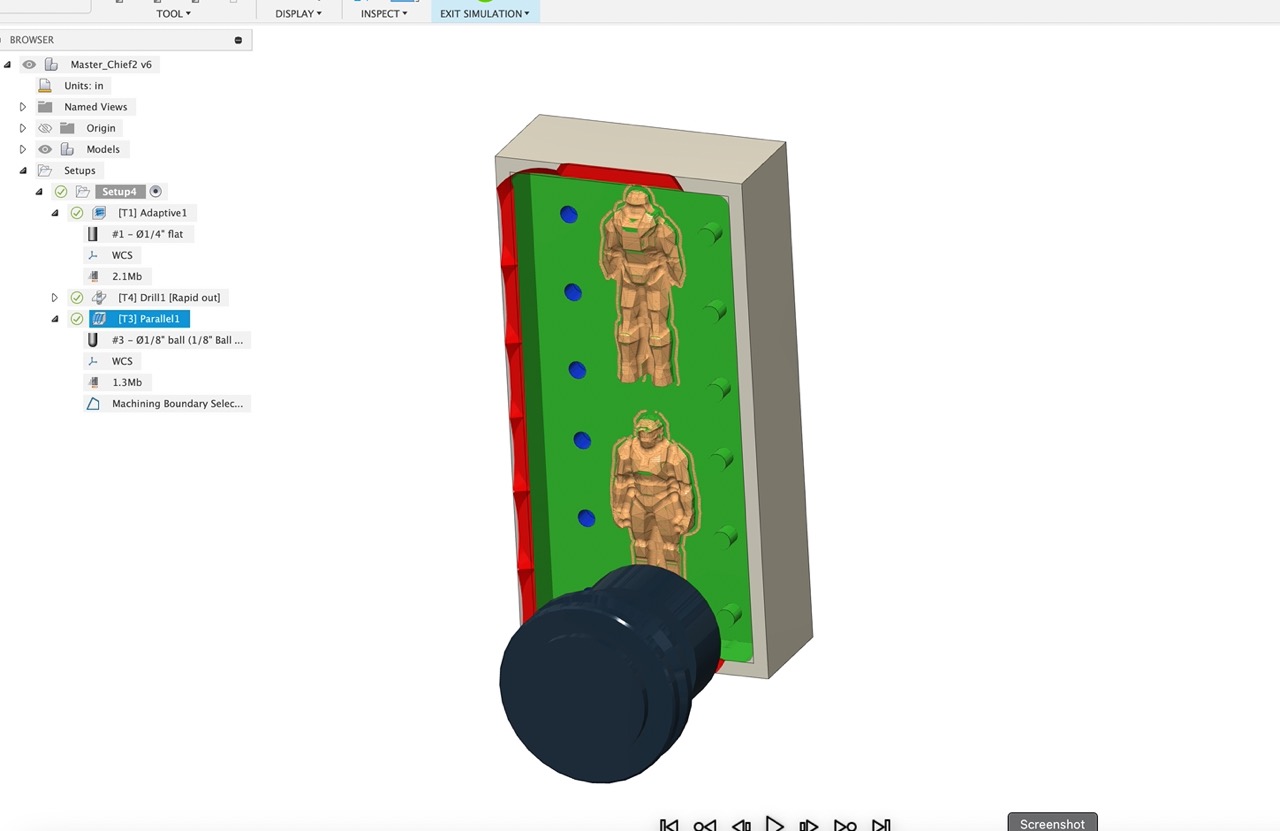

Then assign cam paths to the model such as adaptive clearing and contour

-

The tool paths you should follow the simulation to make sure it will not crash

Splitting Mesh

Splitting Mesh

|

Cam Designs

Cam Designs

|

Tool Path

Tool Path

|

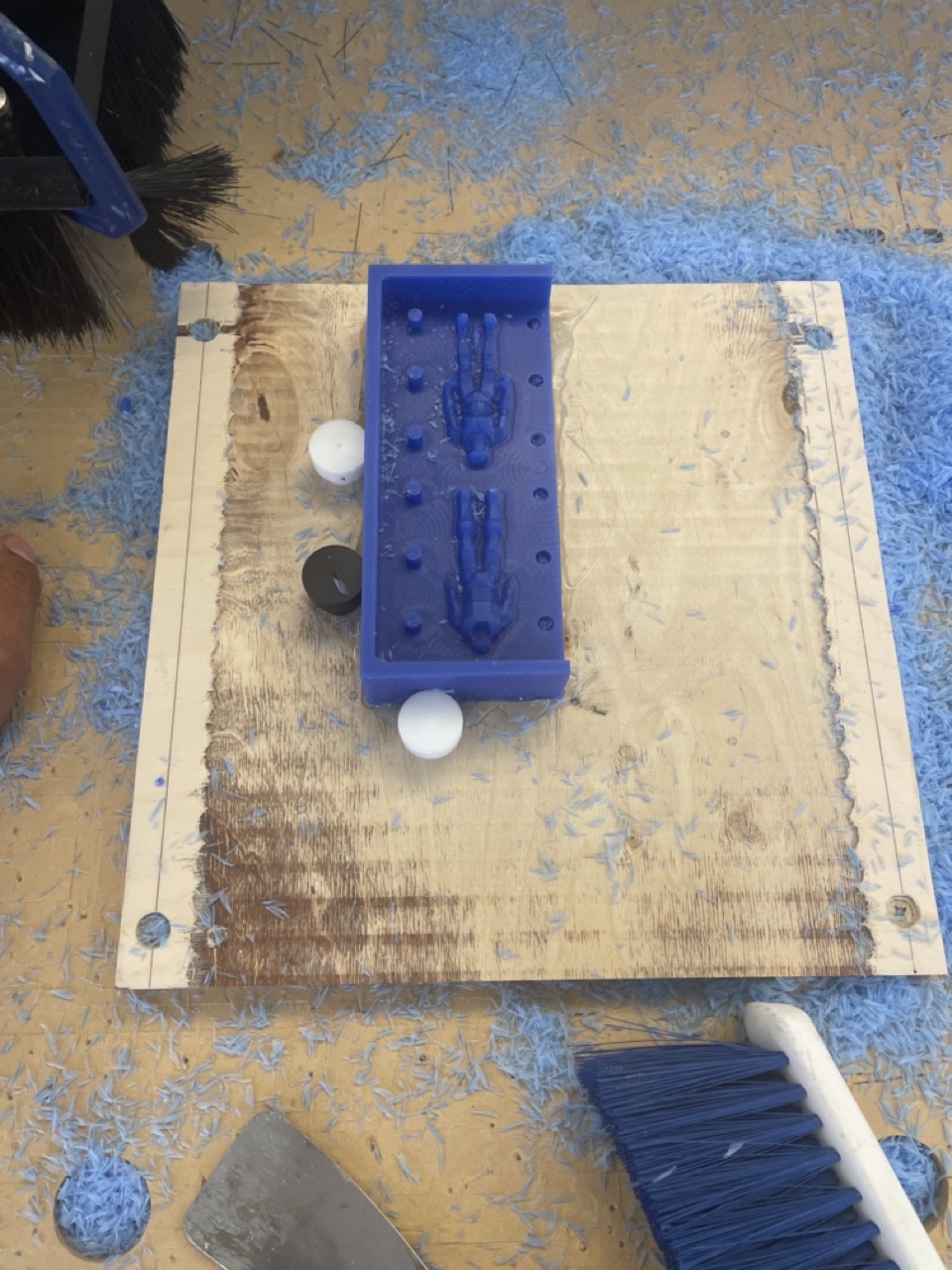

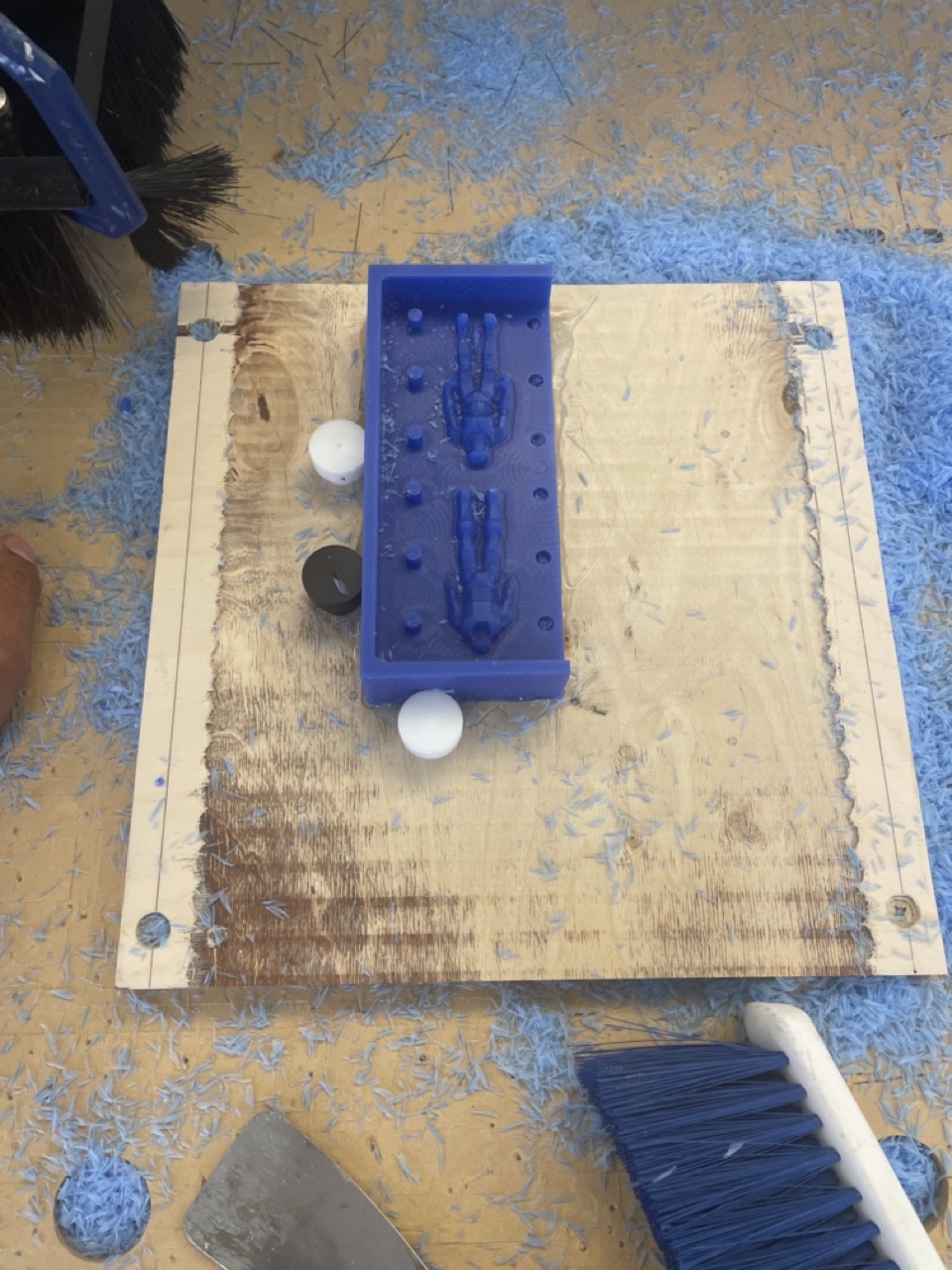

CNC Wax Block

-

I had to grab a wax block to put in the CNC mill

-

I accidentally put wrong dimensions for wax block into cam so one of my walls got wrecked

-

Super glue the block down

-

Put in the first bit

-

Watch the entire process and start at low speed and listen to it First

-

Then I had to change the bit to a smaller one to get the details

-

Clamp a piece of arylic to get last wall

Super Glued Block of Wax

Super Glued Block of Wax

|

Acryllic Block

Acryllic Block

|

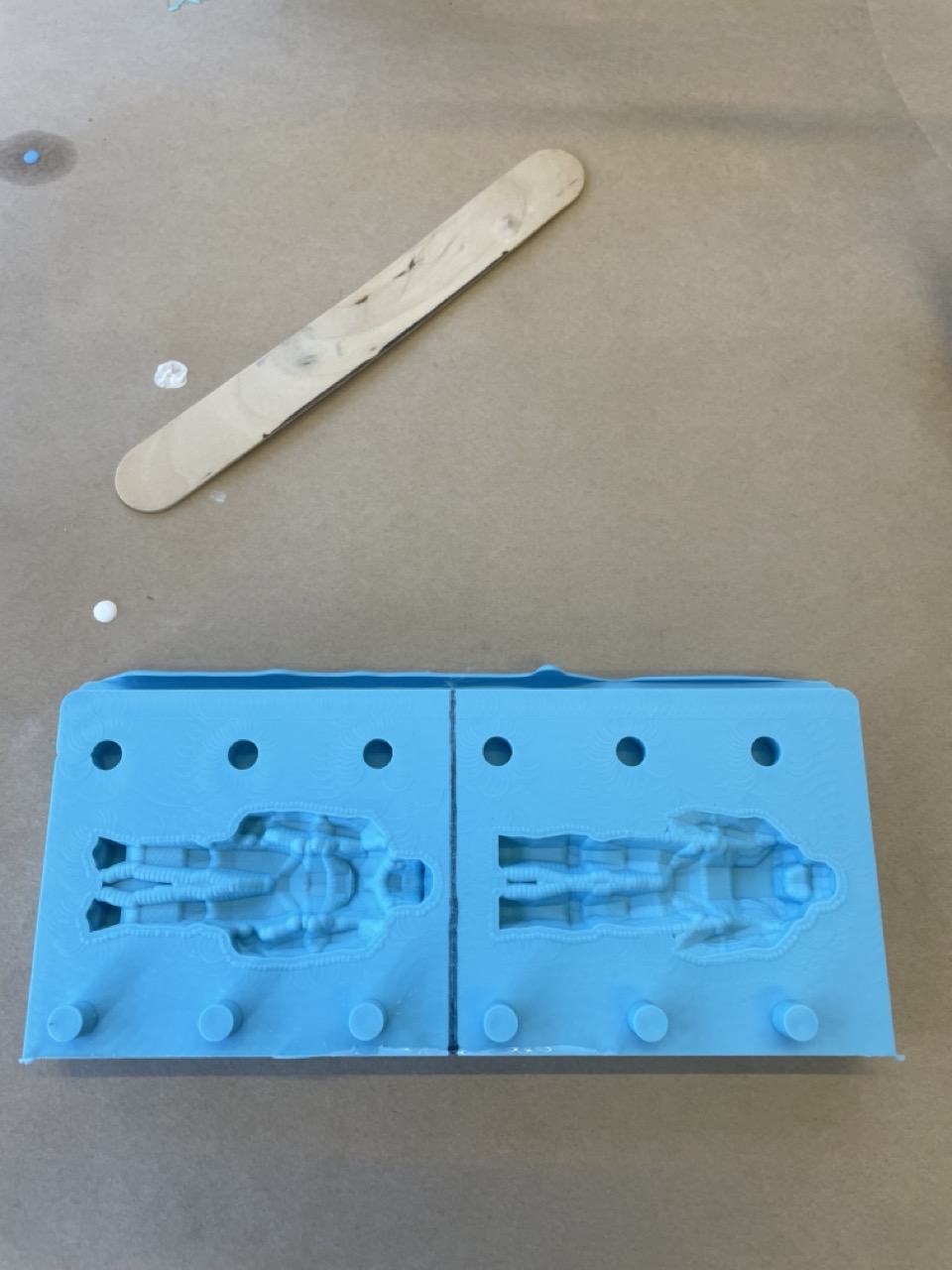

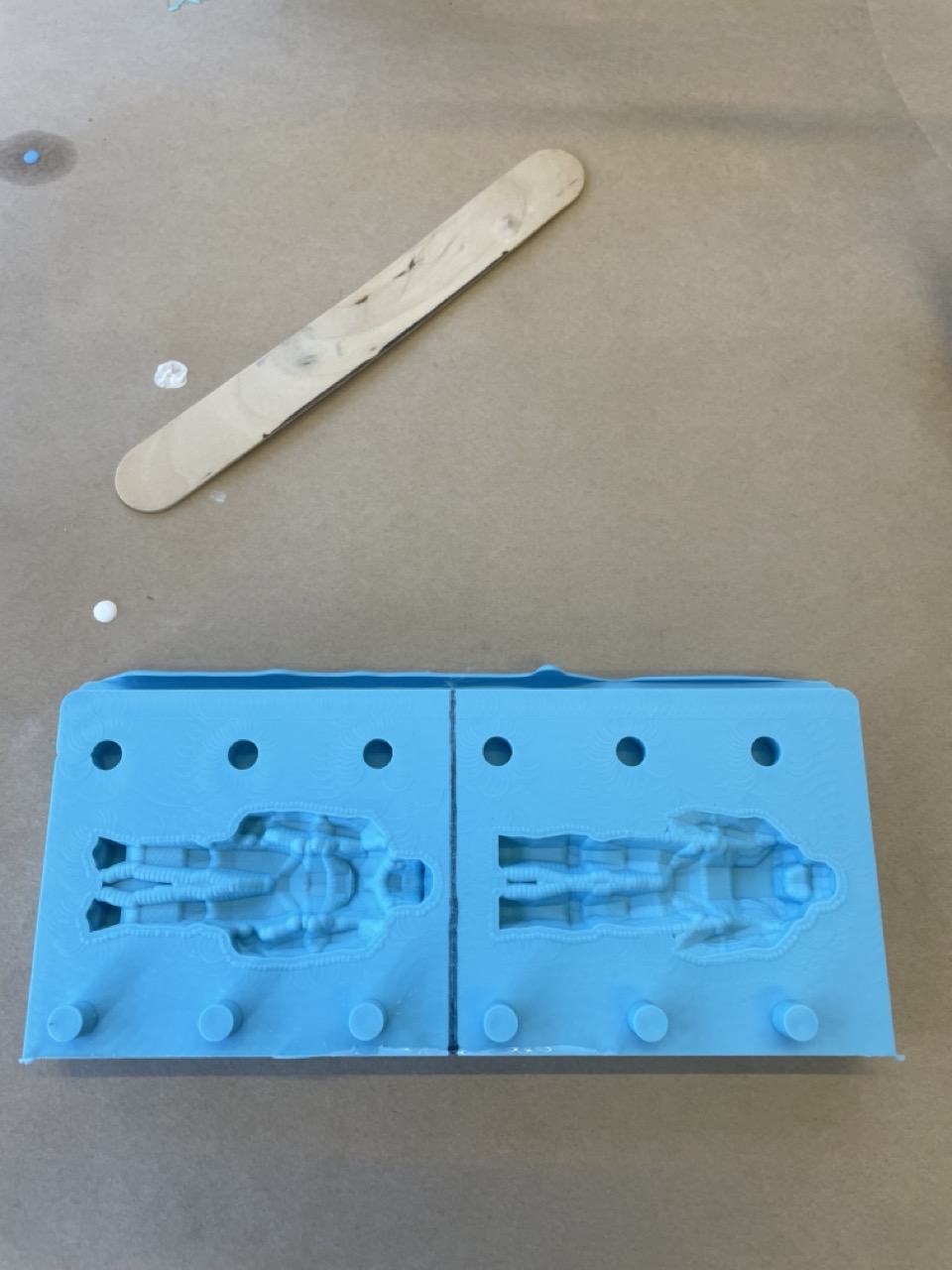

OOMOO Molds

-

I had to mix the two parts of the oomoo together

-

There are rules on how to use it but I kind of eyed

-

I stirrred it for too long, but it was fine hopefully

-

I had to pour it into the mold and then wait for it to dry

-

I tested it by putting water in it and it didnt work so I had to super glue it

-

I had to wait for it to dry and then I had to put the model in the mold

Finished Mold

Finished Mold

|

Clamping Mold Down

Clamping Mold Down

|

Casting

-

I mixed the dry stone with the water

-

Kinda eyed it but kept it watery so it would flow into the mold better

-

Had to cut out cone shapes from the feet cause from the helmet would have been too difficult

Finished Casting

Finished Casting

|

Pirate Chief

Pirate Chief

|

Waiting for Mold

Waiting for Mold

|

Group project link Group Assignment